Heterogeneous integration and IC packaging

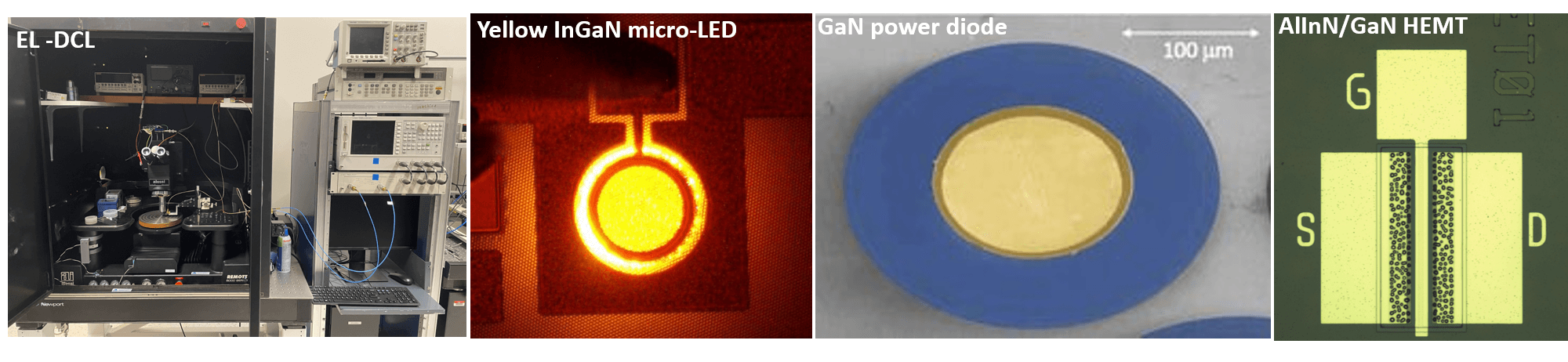

III-Nitride materials, specifically AlInGaN, are a class of semiconductor materials that are widely used in various optoelectronic devices such as LEDs (visible and UV), laser diodes, high-electron-mobility transistors (HEMTs), and power devices. These materials have attractive properties such as high electron mobility, high breakdown voltage, and high thermal stability, which make them suitable for high-power and high-temperature applications.

One of the most important applications of III-nitride materials is in the lighting field, where they are used to fabricate high-efficiency and high-brightness LEDs. These LEDs are highly energy-efficient and have a long lifespan, which makes them ideal for use in a wide range of applications, such as general lighting, displays, and communications.

In addition to lighting, III-nitride materials are also used in the fabrication of laser diodes, which are widely used in telecommunications, optical storage, and other applications. They are also used to fabricate power diodes and transistors, which are used in high-power electronic devices such as power supplies, inverters, and motor drives.

III-Nitride materials have a wide range of applications and have attracted a lot of attention due to their unique electronic and optical properties, making them an important area of research in semiconductor materials and device physics.

Highly Robust Integrated Power Electronics Packaging Technology

At CISEDS, we are dedicated to advancing the field of AlInGaN materials and their applications in various technologies. One area of focus is the growth and characterization of AlInGaN materials through metal-organic chemical vapor deposition (MOCVD). Our capabilities and research efforts in this area include the following:

We are committed to conducting cutting-edge research on AlInGaN materials and their applications. Our research efforts focus on developing new growth techniques, optimizing material properties, and characterizing the materials using advanced techniques. This will enable us to achieve high-quality materials and devices that can be used in a wide range of applications.