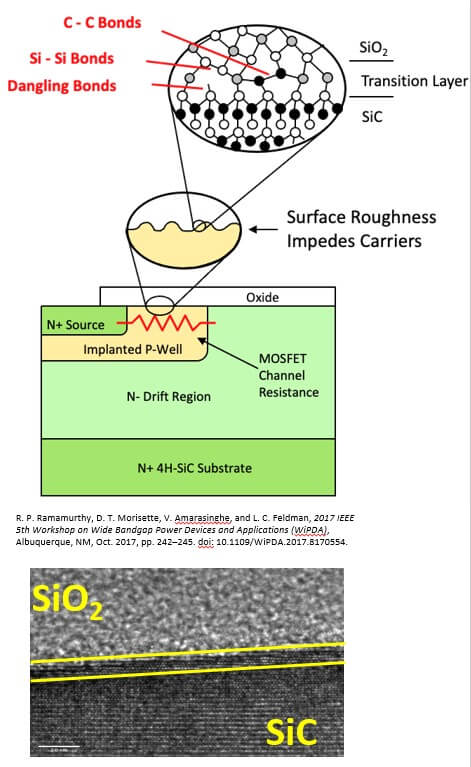

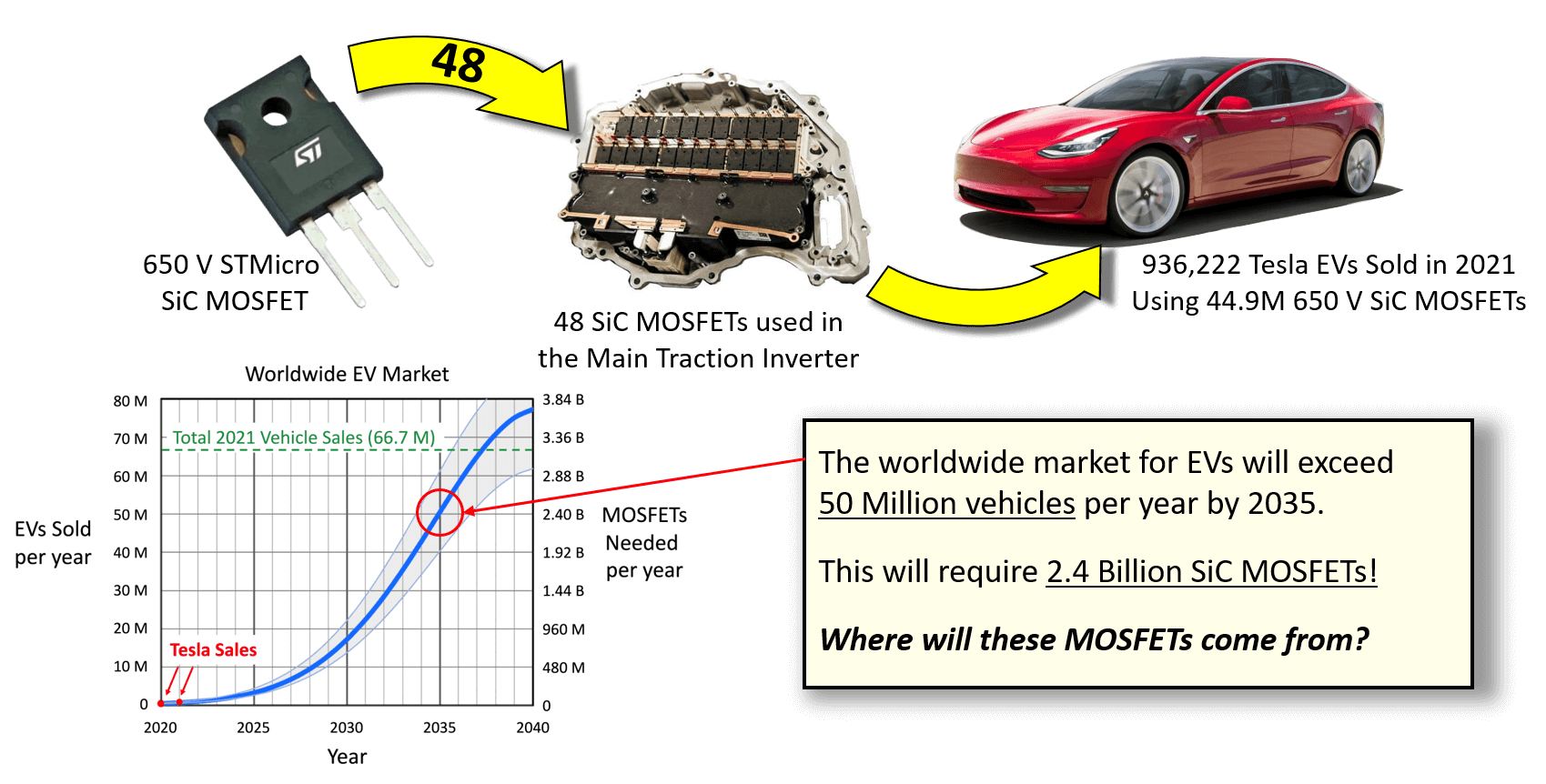

Some of the major challenges facing Next-Generation SiC MOSFETs in their efforts to power the electric vehicle revolution include:

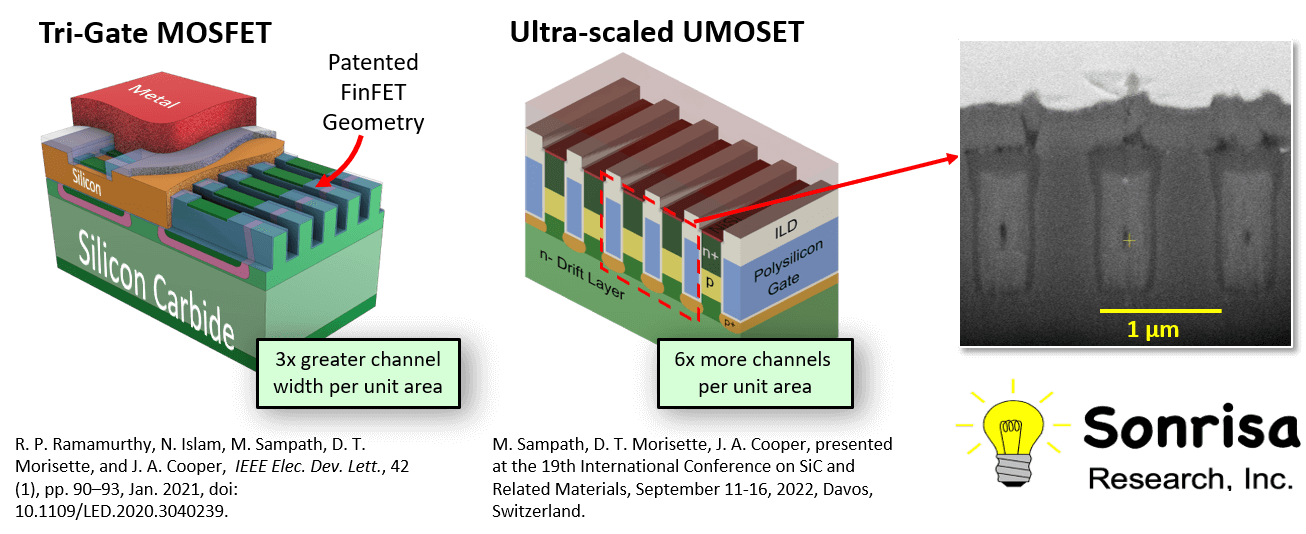

The first approach for reducing the channel resistance in SiC MOSFETs for EV applications follows a series of steps. The steps include: